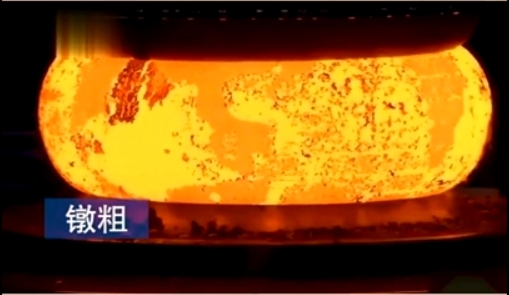

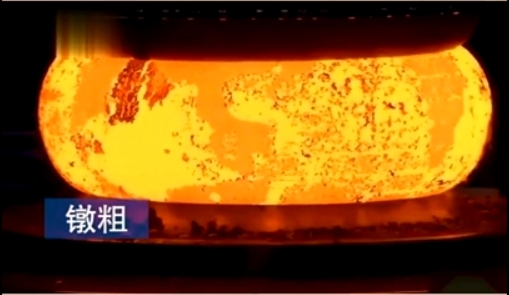

Forging hydrau torcular est maxime solebat praestare omnes processibus liberi cudere, ut turbarentur, elongationem, punching, foraminis enlargement, inclinatio, obsessio, et tondentes metallum plastic materiae. Est primarily usus est producendo faber est ex composito ex sagittas, vectes, laminis, discs, circulos, et quadrata, et late applicantur in fabrica, alloy ferro, et non-ferro, alloy ferro, et alia non-ferrea metalla, et alia non-ferro metalla, et alia non-ferrea, alloy ferro, et alia non-ferro metalla. Hoc offert significant commoda secundum internum et externum qualis from materiae, cede rate, dimensional accurate, automation campester, productio efficientiam, tum environmental tutela et operator salutem.

Huzhou apparatus instrumentum scriptor Free Forging Hydrau Torcular features Humanum-Machina interface input ostentationem, PLC control, et multifunctional et multi-directional realis-vicis magna facultatem. In apparatu imperium ratio praebet manual / junctura opus modos, permittens ad junctura de torcular et operating apparatus in I + I configuratione. Hydrau ratio adoptat modularem integrated ratio cum pelagus cylindrici pressura relevium et celeri descensus dispensata per proportionalem valvulae ad flexibile temperatio et reducitur ictum et vibration. In apparatu fit celeritas transientes lectio munus pro industria, salvis usus et improved efficientiam. Et principalis oleum sentinam potest repulsi a servo motricium, providente commoda ut navitas-salute, sonitus reductionem, et reducitur calor generationem ex oleum redundantiam.

Technical parametri:

| No. |

Contentus |

Unitas |

Cubits |

| 1 |

Nominal Force |

Kn |

8000 |

12500 |

16000 |

20000 |

25000 |

31500 |

40000 |

50000 |

60000 |

| 2 |

Pressura |

MPA |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

| 3 |

Pelagus cylindrum diameter |

mm |

φ630 |

φ800 |

Φ630 / II-φ450 |

φ710 / II-Φ500 |

φ800 / II-Φ560 |

Φ900 / II-φ630 |

Φ900 / II-φ800 |

III-Φ920 |

Φ980 / II-Φ900 |

| 4 |

Spatium |

mm |

2200 |

2600 |

2800 |

3100 |

3200 |

3800 |

4000 |

4500 |

5200 |

| 5 |

Lapsus ictu |

mm |

1000 |

1200 |

1400 |

1500 |

1600 |

1800 |

2000 |

2200 |

2500 |

| 6 |

Spacing inter columnas |

RELICTUS |

mm |

1800 |

2000 |

2200 |

2400 |

2600 |

2800 |

3000 |

3300 |

3600 |

| ANTE |

mm |

800 |

1000 |

1100 |

1200 |

1400 |

1600 |

2000 |

2200 |

2200 |

| 7 |

SLIDER |

Reditus |

mm / s |

300 |

300 |

300 |

250 |

250 |

250 |

200 |

200 |

200 |

| 工作 opus |

mm / s |

50 |

50 |

50 |

50 |

50 |

40 |

40 |

40 |

40 |

| 下行 descensus |

mm / s |

300 |

300 |

300 |

250 |

250 |

250 |

200 |

200 |

200 |

| 8 |

Movabilia worktable magnitudine |

RELICTUS |

mm |

1500 |

1600 |

1800 |

2000 |

2200 |

2400 |

2500 |

2800 |

3000 |

| ANTE |

mm |

3000 |

3000 |

3600 |

4500 |

5000 |

6000 |

6000 |

6000 |

7000 |

| 9 |

Movabilia worktable ictu (ante ad tergum) |

mm |

1000 |

1000 |

1500 |

1800 |

1800 |

2000 |

2000 |

2000 |

2500 |

| 10 |

Movabilia worktable celeritate |

mm / s |

200 |

200 |

200 |

200 |

200 |

200 |

200 |

200 |

200 |

| 11 |

Maximum licita eccentricity |

mm |

100 |

100 |

150 |

200 |

200 |

200 |

250 |

250 |

250 |

| 12 |

Maxime FORTIMBILIS Steel Ingot (upseeting / elongatio) |

T |

2.5 / V |

5/8 |

8/15 |

12/20 |

20/40 |

25/45 |

36/65 |

40/80 |

60/130 |

| 13 |

Installed potentia |

KW |

440 |

660 |

880 |

1100 |

1320 |

1320 |

1650 |

2100 |

2500 |

| Customization is available secundum user vel processus elit. |